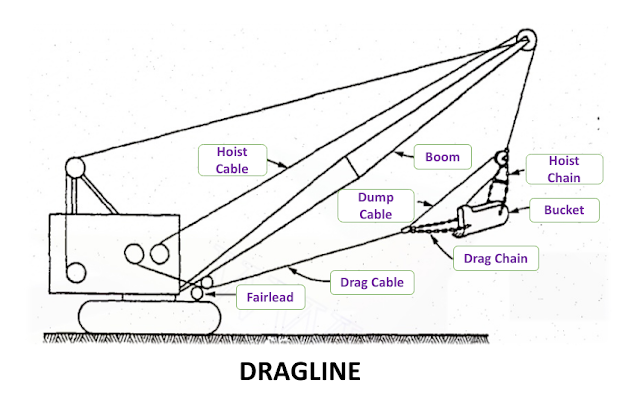

DRAGLINE

Dragline components are :

- A drag bucket

- Fairlead

- Wire ropes are used for the boom suspension

- Drag cable

- Drag Chain

- Hoist Cable

- Hoist Chain and

- Dump Cable

The fairlead will guide the drag cable onto the drum when the bucket is being drawn in-loaded.

The hoist line operates over the boom-point sheave and is used to raise and lower the bucket.

In the digging operation, the drag cable is used to pull the bucket through the material. When the bucket is raised and moved to the dump point, releasing the tension on the drag cable causes the mouth (open end) of the bucket to drop vertically and gravity then draws the material out of the bucket.

SIZE OF DRAGLINE

The size of a dragline is indicated by the scale of the bucket, expressed in blocky yards. However, most cranes might handle over one size bucket, looking on the length of the boom utilised and also the unit weight of the fabric excavated.

The crane boom is angulate comparatively low once operating; but, boom angles of but 35° from the horizontal are rarely sensible due to the chance of tipping the machine.

Because the most lifting capability of a dragline is restricted by the force which will tilt the machine over, it’s necessary to scale back the scale of the bucket once a protracted boom is employed or once the excavated material features a high unit weight.

When excavating wet, sticky material and casting onto a spoil bank, the prospect of tipping the machine will increase due to material jutting within the bucket. In apply, the combined weight of the bucket and its load ought to turn out a tilting force not bigger than 75% of the force needed to tilt the machine.

A longer boom, with a smaller bucket, are wont to increase the creating by removal reach or the merchandising radius once it’s not fascinating to usher in a bigger machine.

If the fabric is tough to excavate, the utilization of a smaller bucket that will scale back the creating by removal resistance may alter a rise in production.

OPERATION OF A DRAGLINE

The excavating cycle begins when the operator swings the empty bucket to the digging position while at the same time releasing the tension on the drag and hoist lines.

There are separate drums on the crane unit for the drag and hoist line cables. Therefore, a good operator can coordinate their motion into a smooth operation. Digging is accomplished by pulling the bucket toward the machine while regulating the digging depth by means of the tension maintained in the hoist cable.

When the bucket is filled, the operator pulls in the hoist cable while playing out the drag cable. The bucket is so constructed that it will not dump its contents until the drag cable tension is released.

Releasing the tension on the drag cable causes the tension on the dump cable and drag chain to also be released, and the front (open end) of the bucket falls vertically allowing the material to slide out.

Hoisting, swinging, and dumping of the loaded bucket follow in that order; then the cycle is repeated.

An experienced operator can cast the excavated material beyond the end of the boom.

Dragline work should be planned to permit most of the digging to be done in the zones that permit the best digging.

- It has a low travel speed.

- It is suitable for soft ground and for large projects.

- It has high travel speed.

- It is suitable for firm ground and for scattered jobs.

- It has also high travel speed.

- It is suitable for firm ground and scattered jobs.

Dragline production will vary with these factors:

1) Type of material being excavated :

The output of a drag line also depends upon the type of material to be excavated. In loose, dry and soft materials output will be more, whereas in hard and tough soil, output will be less.

2) Depth of cut (depth below the base of the dragline’s tracks) :

- The output of a dragline is maximum when it is allowed to work at the optimum depth and at angle of swing 90°.

- The optimum depth depends upon the type of soil and the size of bucket with increase in size of bucket, the optimum depth of cut also increases.

- The angle of swing is the horizontal angle expressed in degrees, between the position of the bucket when it is in excavating position and discharging load into haul unit.

- The time of cycle (digging, swinging, dumping and returning to the digging position) is directly proportional to the angle of swing with increases in the angle of swing, the output of dragline decreases.

4) Size and type of bucket :

In selecting the size and type bucket to use on a project, one should match the size of the lattice-boom crane and bucket properly to obtain the best action and the greatest operating efficiency.

A dragline bucket consists of three parts: the basket, the arch, and the cutting edge. It can be completed with teeth and shrouds (extra metal pieces between the teeth).

Buckets are generally available in three types :

- Light duty

- Medium duty and

- Heavy duty

- Light-duty buckets, sometimes the term lightweight is used, are specifically manufactured for excavating materials that are easily dug, such as sandy loam, sandy clay, or sand. In the appropriate application, they provide greater capacity without sacrificing durability.

- Medium-duty buckets are used for general excavating service. Sometimes the term general purpose is used in reference to medium-duty buckets. Typical applications include excavating clay, soft shale, or loose gravel.

- Heavy-duty buckets, which have comparatively heavier construction throughout, and are armored for maximum strength and resistance to abrasion, are used for mine stripping, handling blasted rock, and excavating hardpan and highly abrasive materials. Buckets are sometimes perforated to permit excess water to drain from the load.

5) Length of boom :

- A longer boom, with a smaller bucket, will be used to increase the digging reach or the dumping radius, when it is not desirable to bring in a large machine.

- Due to longer boom, it is possible of dispose off the earth in one operation, there by saving the cost and time required for employing a hauling unit.

- The boom is generally set at an angle of 30° to 40° to the vertical while working. The usual boom lengths are 50 ft, 60 ft and 70 ft.

6) Size of the hauling unit :

Skilled and experienced operator should be employed to get more output.

8) Job conditions :

- A large job having large open space with a firm and well drained floor, where the trucks can be placed on either side of the dragline is called an excellent job condition where the output of a dragline will be more.

- Uniform level ground, where the height of cut is approximately equal to the optimum depth of cut, also provides good job conditions.

- The haul road should not be affected by rains.